In the rapidly evolving world of manufacturing, subtractive manufacturing has emerged as a cornerstone technique, revolutionizing the production of complex parts and components. This method, distinguished by its precision and efficiency, plays a crucial role across various industries, from aerospace to automotive. Let's delve into what makes subtractive manufacturing a game-changer and why it's gaining traction in modern production processes.

What is Subtractive Manufacturing?

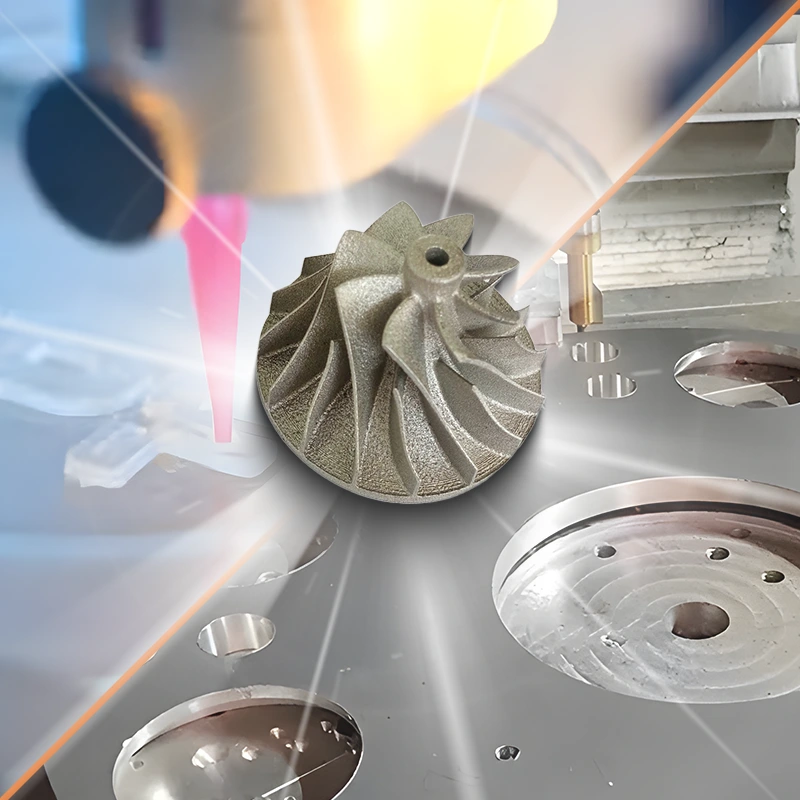

Subtractive manufacturing refers to a process where material is systematically removed from a solid block, or "workpiece," to achieve the desired shape. This is typically done using tools such as mills, lathes, and routers. Unlike additive manufacturing, which builds objects layer by layer, subtractive manufacturing works by cutting away material to reveal the final product.

Key Benefits of Subtractive Manufacturing

High Precision and Accuracy: Subtractive manufacturing is renowned for its exceptional precision. CNC (Computer Numerical Control) machines, a common tool in subtractive processes, can achieve extremely tight tolerances and fine details, making it ideal for producing intricate parts used in high-tech industries.

Material Versatility: This method can work with a wide range of materials, including metals, plastics, and composites. This versatility makes it suitable for various applications, from producing lightweight aerospace components to durable automotive parts.

Efficient Material Use: By removing material from a solid block, subtractive manufacturing minimizes waste compared to some other methods. This not only contributes to cost savings but also supports sustainable practices by reducing excess material disposal.

High-Quality Surface Finish: The final surface finish achieved through subtractive manufacturing is often superior, requiring less post-processing. This is particularly advantageous for parts that need to meet stringent aesthetic or functional standards.

Applications of Subtractive Manufacturing

Aerospace Industry: Precision components such as turbine blades and structural parts are manufactured using subtractive techniques to meet rigorous performance standards.

Automotive Industry: Custom parts, engine components, and prototypes are produced with high accuracy, contributing to vehicle performance and safety.

Medical Devices: The production of implants, prosthetics, and surgical tools benefits from the fine details achievable with subtractive manufacturing.

The Future of Subtractive Manufacturing

As technology advances, subtractive manufacturing continues to evolve. The integration of advanced software and automation enhances the capabilities of CNC machines, allowing for even greater precision and efficiency. Innovations such as multi-axis machining and hybrid manufacturing processes are pushing the boundaries, enabling the production of more complex geometries and improving overall production speeds.

Click here for more information:-